What are the coil spring buffers?

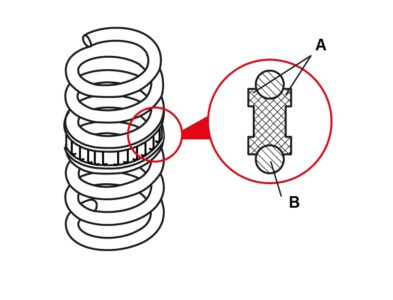

Coil spring buffers are rubber elements that, mounted between the coils of the springs, harden the suspension and increase its stabilization. The buffers are made of an appropriate rubber mixture. They have a special cavity that facilitates a stable setting between the coils of the springs without the use of additional mounting elements.

Why use rubber buffers?

Thanks to the use of coil spring buffers, the ground clearance in the car is increased, and the hardening of the suspension allows you to carry a heavier load without lowering the suspension too much. Depending on your needs, you can use one to three buffers for one spring.

How to install the coil spring buffers in the car?

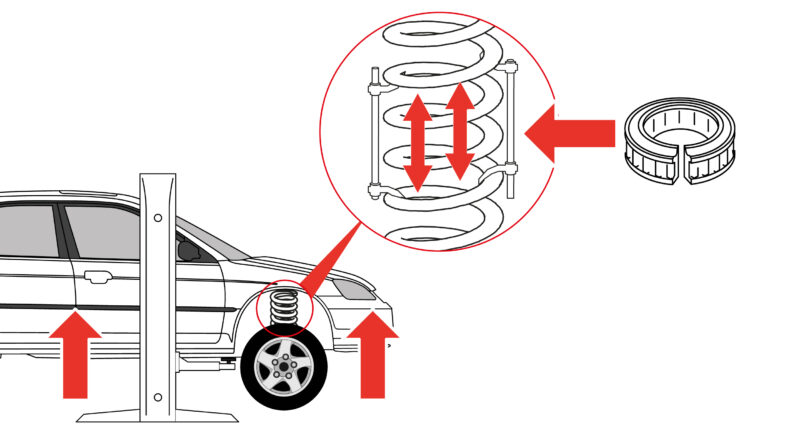

We below present brief information on how to mount the buffers between the spring coils. The whole process is not complicated and is carried out without dismantling the spring. During assembly / disassembly, particular care should be taken to ensure that the car is stable on the jack.

1

Place the car on the jack to stretch the spring. REMEMBER! The insert assembly process is performed without disassembling the spring.

If lifting the car does not make it possible to mount the insert to the springs, use spring compressors. The pullers must be attached the other way around in order to stretch the spring. It is best to mount them between four turns.

Place the buffer in the middle of the coil spring height, winding it on coils.

REMEMBER to mount buffers in the same height and quantity on both sides of the car!

2

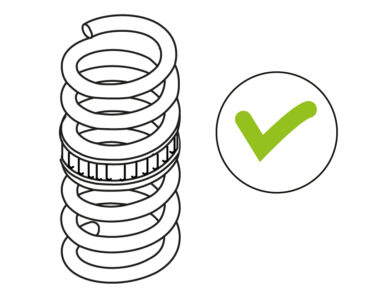

After lowering the car from the jack, make sure that the collars of the insert are wrapped in the spring.

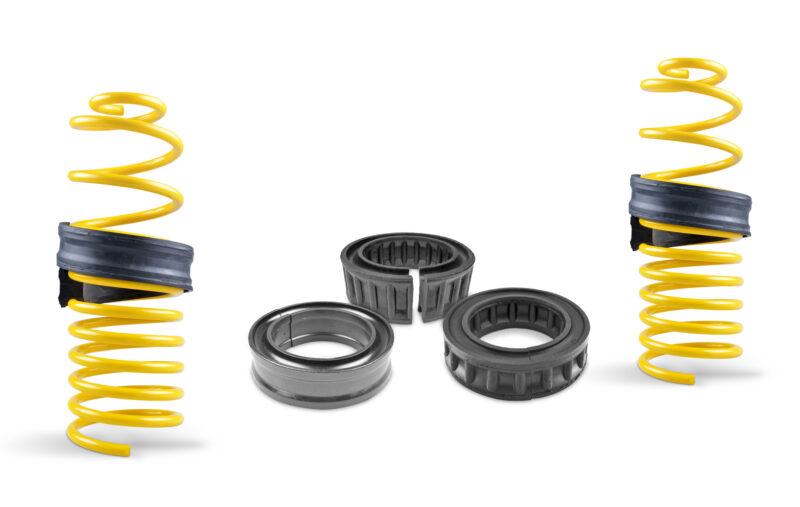

Coil spring buffers in our offer

We offer spring buffers in 3 sizes. They fit most passenger cars, vans and SUVs.