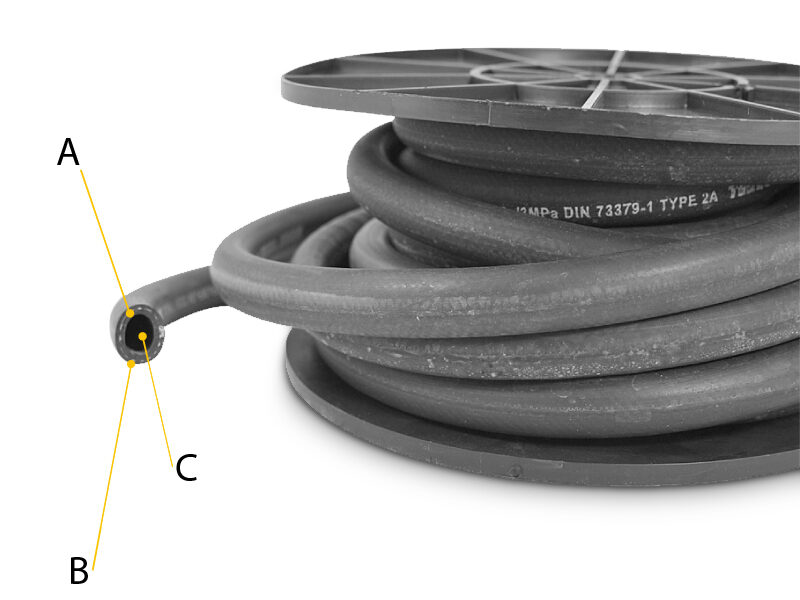

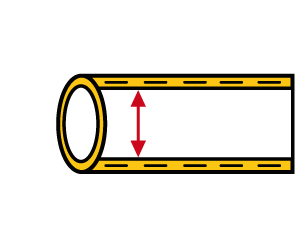

Fuel-line hoses are a very important element of cars with internal combustion engines. Good quality and durability of the hoses are crucial for the proper supply of fuel to the power unit. It should be remembered that as a petroleum product, fuel dissolves some rubber mixtures and ordinary rubber hoses cannot be used. It is important that the fuel line meets strict requirements regarding exposure to changing weather conditions. Therefore, the lines must be resistant to both the fuel and external factors, as well as to the pressure prevailing inside. The material from which the fuel line is made must be resistant to temperature and kinks as well as to fuels. Only 3-layer fuel-line hoses are able to meet all requirements, as each layer has a different task that cannot be achieved by any of them separately.

How are fuel hoses constructed?

Our fuel-line hoses have the following 3 layers.

Outer layer

Synthetic CR (chloroprene rubber) black, smooth

Resistance to:

ozone, acid, abrasion, aging by temperature, weather conditions, synthetic and mineral oils, sunlight

Middle layer

High-strength textile braid

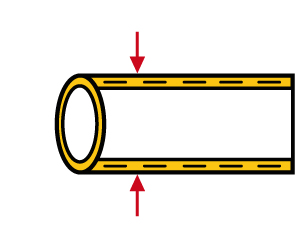

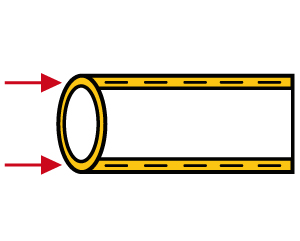

Resistance to:

pressure, bending

Inner layer

Synthetic NBR (acrylonitrile butadiene rubber) black, smooth

Resistance to:

fuels*, oils, crude oil, lubricants and fluids based on mineral and glycol

*NBR rubber is not suitable for E85 fuel

What are the features of our fuel-line hoses?

Our fuel lines have the following properties:

Working temperature range: -35°C do +90°C

Peak temperature: +110°C

Maximum working pressure: 145 psi (10 bar)

Bursting pressure: 435 psi (30 bar)

What diameters of fuel-line hoses do we offer?

The hoses are available in rolls (10 or 15 meters) and in one meter lengths in 12 internal diameters from 3.2 to 20 mm. The full offer is available in our free online catalogue at: http://katalog.tedgum.pl